Unique Custom Designed, Printed and Clear Cello & Poly Bags

Cellophane vs Polypropylene, which is better? Neither is better or worse. Compare the pro’s and con’s below.

Do you have a unique custom bag in mind? Atlanta Cello and Poly can help you create a custom bag that works for you! We’ve got your PERFECT Bag!

Types of Cellophane and Polypropylene Bags to Consider

You have options when it comes to bag selection.

In addition to material preference, you can choose bag thickness and design. Select what works best for you and remember, we can guide you every step of the way!1-2 Mil

Common film thickness for a variety of flexible packaging needs. Non-laminated bags can be: 1.2 – 1.4 – 1.6 – and 2.0 mil thickness.

3-5 mil

Film in this range is thicker and stronger. Most stand-up pouches use this thickness for strength and performance. These bags can be metalized and contain polyester as well as many other structures

Hang Holes

Hang-holed bags are best for product that will be displayed on a rack. All of our flat- and pouch-bags can be made with this feature. A typical hang hole can be a circle or sombrero punch.

Flat Bag Types

We can make bags that require either a lap seal or fin seal. Also, we can produce side gusseted flat bags as well as bags that have a folded bottom for standing bag applications.

Color Options

We print spot colors, process printing, and even digital printing. Each printing style deserves its own purpose and we can help you determine the best fit.

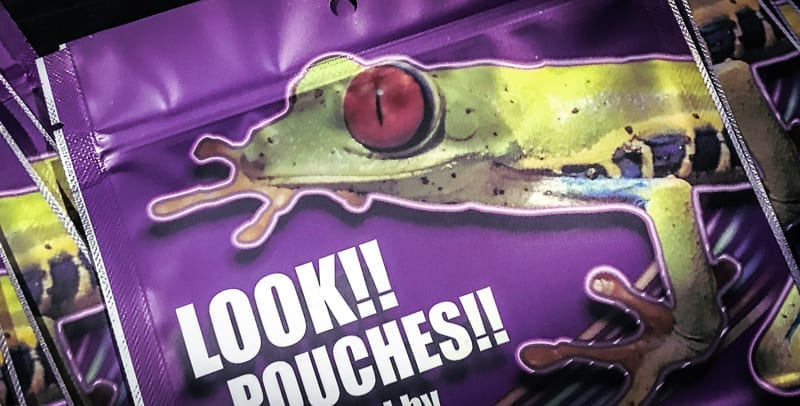

Stand Up Pouch

Widely popular, bags featuring a zipper closure come with a tear notch for first-time opening. These bags can be considered stand up pouches or flat bags with two or three side seals. Hang Hole, Tear Notch, Rounded Corners, and 1” to 8” Bottom Gusset are available options.

Tamper Evident

Tamper evident bags are sealed at the top of the bag and can be bottom filled for resale. Shows a neat appearance and is considered tamper-proof for the consumer.

Vent Holes

Providing a breathing hole in bags is important for fruits and vegetables. Vent holes can be added to any Atlanta Cello and Poly bag.

Our Custom Printing Process

Let us help you design a branded cellophane or polypropylene bag to create an instant connection with your customers and keep your product and company fresh in their memories. We work with a trusted network of top tier printers that have worked in virtually every industry and understand the value of custom branding. We can help you create a long-lasting impression that builds strong relationships with your customers.

Printing Technology

Our printing technology consists of an 8-color flexography press for spot printing and process color printing. We have the ability to surface print or laminate your printed structure for better durability and film performance. We also offer digital printing which has revolutionized the way the printing industry has viewed short to long run, full color, and variable data printing. Digital printing does not require the processes of making plates or inking up the press, reducing set-up time and labor, and lowering prep charges for you.

Is a Minimum Quantity Required?

No, unlike other companies who require high minimum quantities, we can easily work with small minimums. The minimum quantity depends on the poundage of film required, which depends on the size of your cellophane or polypropylene bag and film thickness.

Satisfaction Guaranteed!

Not 100% pleased with the printing process? Did you need a different color, for example? We’ll do whatever it takes to get you a custom printed bag that you will be proud to present to your customers.

Polypropylene vs Cellophane or

Cellophane vs Polypropylene

What Type of Bag Should I Choose?

The FDA has approved both cellophane and polypropylene bags for use in packaging consumer and business products. Neither is ‘better’ than the other – just different. Here are the basic advantages and disadvantages.

Cellophane

Cellophane is a Natural Product 100% Biodegradable Eco-Friendly & Non-Pollutant Has Excellent Water Vapor, Gas & Fragrance Barriers High Gloss Transparency FDA Approved

Cellophane is a paper product made from the wood pulp of cottonwood trees and has been manufactured since the mid-1930s.

Cellophane has excellent water vapor, gas and fragrance barriers. It is 100% FDA approved, contains a high gloss transparency, is oil and grease resistant, and is anti-static. Cellophane has excellent dead-fold characteristics, is much easier to wrap and manipulate, and will not revert back to its natural design and structure.

Although cellophane cost more to produce than polypropylene, its product consistency is far superior for the value. Cellophane has high permeability that allows moisture to pass through the product preventing condensation, which reduces the risk of mold. This gives items a longer shelf-life. For example, cigars require cellophane’s permeability to moisture since they must be allowed to “breathe” while in storage.

Pros & Cons

A natural organic product. Eco-friendly, which is also a powerful marketing feature for customers.

More breathe-able for moisture, so works better for chocolates and other foods requiring moisture permeability.

Natural dead-fold holds its shape.

right, glossy transparency truly showcases products.

Cellophane’s sticky nature actually works for and against it. With some products, this may annoy your customer by making unwrapping inconvenient.

Cellophane easily rips and tears, and is weaker than polypropylene, which means pointed products inside could easily tear it.

Cellophane has a limited product shelf-life. If you need to bag a food product that may be on the shelves for a while, you may want to consider polypropylene or our premium acrylic coated polypropylene bags.

Polypropylene

Poly has Excellent Clarity Moisture & Oxygen Resistant Has a Longer Shelf Life (Acrylic Coasted Film) FDA Approved

Polypropylene (“poly”) bags are economical and a great value for the money. They are suitable a variety of products, such as dried fruits, nuts, cookies, spices and chocolate. Other popular uses include photos, flower sleeves, portfolios, stationary, potpourri, soap, gifts and sterile products.

Polypropylene bags must be heat sealed, taped or tied for closure to protect the contents enclosed within. Unlike cellophane bags, poly bags do not have a natural dead-fold and resist winkling when folded.

Pros & Cons

Costs less than cellophane. Consider this option when you need functional (vs. beautiful) packaging.

High clarity and quality are comparable to cellophane. Natural crinkle sound when handled.

Does not have natural dead-fold (i.e., a dead-fold is film that sticks to itself). These bags will not wrinkle as easily as cellophane.

More protective than cellophane.

Stiffer, resists tearing.

Excellent oxygen and moisture barrier to protect a bag’s contents.

Avoid polypropylene bags when a bag requires use at high temperatures, for example, with food products that require reheating in the oven. (NOTE: Atlanta Cello and Poly does have special polyester bags which can be microwaved and used with grilling products.)

Avoid polypropylene bags if you have products that requires moisture breathability.